Roof Trusses

Roof trusses are highly engineered pieces of lumber connected by metal plates to form a web that supports a roof structure.

Benefits of a Roof Truss

- Structures can be enclosed more quickly when trusses are used, saving time at the job site and possibly avoiding weather-related delays.

- Exterior walls and many roofs can be erected without the placement of interior bearing partitions, creating one large, open living space.

- This openness allows for entire ceilings and walls to be finished with drywall sheets, up to 1 feet in length, installed uncut. Rough and finish flooring can be laid over the entire area. Cutting and fitting around partitions is eliminated.

- The ability of trusses to have large, clear spans offers complete flexibility for the use of interior space, in line with the more progressive approach to building design. Partitions under clear spanning trusses can be moved without compromising the structural integrity of the building.

- Pre-engineered roof trusses construction eliminates guesswork, provides a more uniform roof appearance and speeds the construction process.

- Waste due to cutting errors in conventional framed roof construction is diminished.

- Pilferage on the job site lessens because engineered trusses generally can not easily be used on other projects.

- Less expensive carpentry labor can be used to install trusses, reducing labor costs.

- Trusses decrease the possibility of material shortage delays because roof framing is supplied in one material package.

- Trusses manufactured with dry lumber do not warp, twist, creating a framing system that is easy to properly place and sheath.

- By eliminating interior bearing walls, trusses also save the cost of interior foundation walls, interior partition top plates and headers.

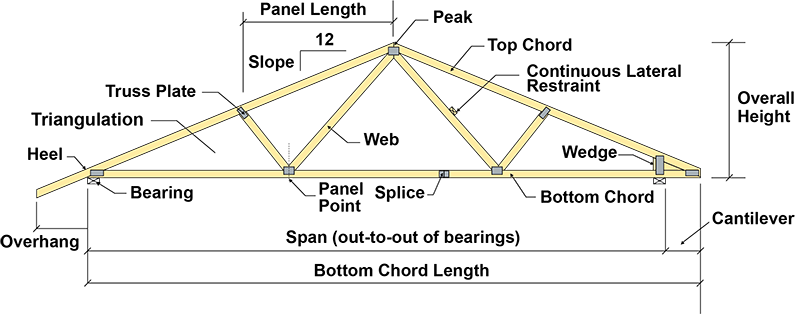

Elements that Make a Roof Truss

- Bearing: Structural support, usually a beam or wall, that is designed by the building designer to carry the truss reaction loads to the foundation.

- Bottom Chord: Inclined, or horizontal member that establishes the bottom of a truss, usually carrying combined tension and bending stresses.

- Cantilever: Part of a truss that extends beyond its support, exclusive of overhang.

- Continuous Lateral Brace (CLR): A line of continuous structural members to a chord or web member of a truss to reduce the laterally unsupported length of the Truss member. The CLR must be properly braced to prevent the simultaneous lateral deformation and/or buckling of the series of truss members to which it is attached due to laterally imposed Loads on, and/or the accumulation of buckling forces within, the truss members.

- Heel: The point on the truss where the top and bottom chords intersect.

- Overall Height: Vertical distance between bearing and the uppermost point of the peak.

- Overhang: Extension of the top chord of a truss beyond the outside of the bearing support.

- Panel Length: Horizontal distance between the centerlines of two consecutive panel points along the top or bottom chord.

- Panel Point: Location on a truss where the web members and top or bottom chords intersect and are connected by metal connector plates.

- Peak: Point on the truss where the sloped chords meet.

- Slope/Pitch: Incline of the roof described as inches of rise over inches of run. For example, 5/12 is 5 inches of rise over 12 inches of run.

- Span: Horizontal distance between outside edges of exterior bearings.

- Splice: The location at which two chord members are joined together to form a single member. It may occur at a panel point or between panel points.

- Top Chord: Inclined or horizontal member that establishes the top member of a truss.

- Triangulation: The act of forming rigid triangles with objects adequately fastened together.

- Truss Plate: Truss plates are manufactured with steel protected with zinc or zinc-aluminum alloy coatings or their stainless steel equivalent. They are designed to laterally transmit loads in wood and are manufactured to various sizes, thickness, and gauges.

- Web: Members that join the top and bottom chords to form the triangular patterns typical of trusses. These members typically carry axial forces.

- Wedge: Triangular piece of lumber that has one side equal to the standard 2 inch dimension lumber widths, and is inserted between the top and bottom chords, usually to allow the truss to cantilever. Its use is determined through engineering analysis.